Insulation

EPS is an oil derivative and thus sensitive to fire. The so called F grades of EPS, are less flammable that conventional EPS and will not combust or self ignite until temperatures of 497°C have been reached. (Bear in mind that wood self ignites at 290°C) When EPS is used inside the house or aparment, it should of course be isolated from the rest of the room with adequate means of protection, like plaster or gypsum.

Using EPS

EPS in very easy to work with. The material is light and can easily be cut in place or into shape using a common wooden saw or a knife. No dust is formed when the material is used and no special clothing or dust masks neccesary. The material will not change its shape at temperatures between -180°C and +80°C. It is however neccesary to protect the plastic from fire and sources of excess heat with a coating of plaster or some other type of fire and heat resistant material according to building regulation article 135.10 regarding fire and fire hazards.

EPS is commonly placed underneath a plaster coating, be it on the interior or exterior of the wall facing the outside. Such an insulation must have a good moisture resistance as it could easily absorb moisture from the plaster coating and thus increased the migration of humidity within the wall. Should the insulation become frosen, which of course does not happen with an insulation that does not absorb water, it could easily rupture the plaster coating. Furthermore moist insulation can easily reach temperatures of 50-60°C on a sunny day if the coating is of dark colour. It is thus apparent that the affects of sudden temperature changes, which we are so used to in Iceland, can significantly affect the wall system and this needs to keep in mind during the design stages.

Sound insulation

A special sound insulation was recently introduced to the Icelandic market. This has been known as "Trittschall" or "step insulation" in countries like Germany. It is very well suited to diminish the sound of footsteps or shoe sounds between floors in apartment buildings. We are still waiting for test results under Icelandic conditions, but comparisons with other tests from institutions in Europe leed us to believe that the Icelandic results will be promissing.

Strength

EPS is extremly light and one would assume that a material of this nature would be very weak or flexible. This is not the case when it comes to EPS. It is considerably strong and posseses many other desirable properties than just Insulative. EPS insulation of density 16 kg/m3 has a compressive strength of about 90 KPa, (9 tonnes per square meter). EPS of density 24 kg/m3 however has a compressive strenght of about 175 KPa. These number consider a deformation of about 10% under the load.

EPS is extremly light and one would assume that a material of this nature would be very weak or flexible. This is not the case when it comes to EPS. It is considerably strong and posseses many other desirable properties than just Insulative. EPS insulation of density 16 kg/m3 has a compressive strength of about 90 KPa, (9 tonnes per square meter). EPS of density 24 kg/m3 however has a compressive strenght of about 175 KPa. These number consider a deformation of about 10% under the load.

EPS insulation of density 20 kg/m3 has a flexural strenght of 270 KPa and a tensile strength of 275 KPa. Due to the high compressive strength, EPS is a prime candidate for applications which demand high resistance to various outside stresses. The flexural stregth of EPS is in many cases a great asset and for instances EPS can play a part in the structural elements of a house with subsequent light structures and savings in material costs.

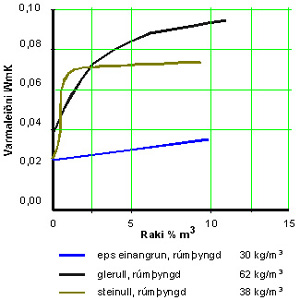

The effect of moisture

Most materials are considered hygroscopic, i.e. they obtain moisture from their surroundings. The relation of air humidity and material humidity is important when insulation properties of materials are to be assessed. The thermal conductivity of water is for example around 0,55-0,58 W/mK, which is around 20-25 times more than the thermal conductivity of air, wich is about 0,024 W/mK. Thus we can deduct that wet or moist material will have a higher coefficient of thermal transmission than dry ones. EPS which is about 16 16 kg/m3 has a moisture content of about 0,1% of its weight when it leaves the factory. The thermal conductivity generally rises by about 0,3% with every 1% increase in moisture, or from 0,037 to about 0,0371 W/mK. However EPS will has a very low tendency to absorb moisture compared to many other insulative materials. EPS insulation of 18 kg/m3 will for example only take up about 0,1-0,4% of its volume of water by lying in 20°C hot water for about 24 hours.

Most materials are considered hygroscopic, i.e. they obtain moisture from their surroundings. The relation of air humidity and material humidity is important when insulation properties of materials are to be assessed. The thermal conductivity of water is for example around 0,55-0,58 W/mK, which is around 20-25 times more than the thermal conductivity of air, wich is about 0,024 W/mK. Thus we can deduct that wet or moist material will have a higher coefficient of thermal transmission than dry ones. EPS which is about 16 16 kg/m3 has a moisture content of about 0,1% of its weight when it leaves the factory. The thermal conductivity generally rises by about 0,3% with every 1% increase in moisture, or from 0,037 to about 0,0371 W/mK. However EPS will has a very low tendency to absorb moisture compared to many other insulative materials. EPS insulation of 18 kg/m3 will for example only take up about 0,1-0,4% of its volume of water by lying in 20°C hot water for about 24 hours.

Shrinkage and after shrinkage

Directly after production the EPS block can shrink by as much as 1%. Aftershrinkage is measured after 24 hours, when the surplus espansion gasses have been released from the block. This release can take as long as one day to several weeks. Depending on the ratio of density and volume. EPS can shrink by as much as 0,3% during the first 6 weeks, wich is insignificant, but on a long continious section this can be noted. After 6-8 weeks at the correct temperature no further shrinkage is expected in EPS insulation from Tempra hf.